685.AXS.032.B00

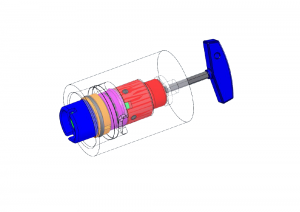

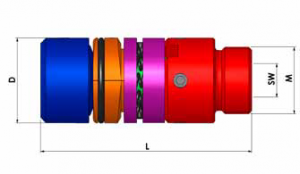

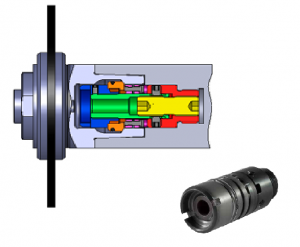

HSK-A/C/E32+B/D/F40 Axial-Clamp Manual Gripper

| HSK-A | HSK-B | Key Size | Torque | Force | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 32 | HSK-B/D/F 40 | 3 | 6 Nm | 12 kN | 685.AXS.032.B00 | |||

| HSK-A/C/E 40 | HSK-B/D/F 50 | 4 | 11 Nm | 16 kN | 685.AXS.040.B00 | |||

| HSK-A/C/E 50 | HSK-B/D/F 63 | 5 | 18 Nm | 24 kN | 685.AXS.050.B00 | |||

| HSK-A/C/E 63 | HSK-B/D/F 80 | 6 | 24 Nm | 30 kN | 685.AXS.063.B00 | |||

| HSK-A/C/E 80 | HSK-B/D/F 100 | - | - | - | 685.AXS.080.B00 | |||

| HSK-A/C/E 100 | HSK-B/D/F 125 | - | - | - | 685.AXS.100.B00 |

For more information regarding this item (HSK-A/C/E32+B/D/F40 Axial-Clamp Manual Gripper) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

Steep Taper Tool Changer Alignment Gauge Instruction Manual

The tool changer alignment gauge is designed to verify correct alignment of the machine spindle to the tool changer. See PDF for full instruction manual.

HSK-E Tool Holder Blanks

TAC Rockford stocks HSK-E32, HSK-E40, HSK-E50, and HSK-E63 blanks in a variety of diameters and lengths. Other sizes are available

- contact us with your requirements.

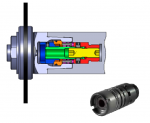

Axial Collet Clamping Grippers for HSK 100 Grinding Wheels

The AZS gripper is specially designed to manually mount heavy grinding wheels to a standard HSK 100 tool interface. The grinding wheel is mounted onto a HSK-style tool holder and is held to the spindle extremely accurately. The gripper allows very high clamping forces in a compact design. For example, the clamping force is 55 kN with a clamping torque of only 30 Nm for HSK 100. If needed, this AXS-100 gripper could be adapted for any HSK standard.

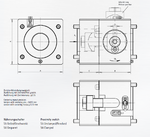

Hollow Taper Shank Type C

Preferably for use with spindles in transfer lines and special-purpose machines without automatic tool changing, stub spindles, extensions or reducers. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

Manually Operated Swing-out Style Transfer Rail Couplings

The mechanical self-locking swing-out style gripper rail coupling is designed for manual coupling of gripper rails on transfer presses. A short lift-out stroke is required for changing the tool. An axial stroke is required in the event of additional centering with pins. The coupling consists of a hard anodized aluminum housing, a swiveling tensioning rod and a self-locking eccentric cam gearing. This configuration allows high clamping forces and features a high dynamic rigidity with minimum mass.

Stationary Electromechanical Gripper Style Clamping Systems

Electromechanical gripper style clamp for die clamping on sides. When unclamping the collet opens in order to disengage the draw bolt of the die.

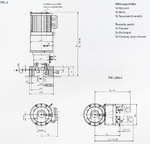

Hollow Taper Shank Type D

For use in all areas which require even better support with manual tool changing via a large contact face. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.