291-OHL-OHLK

BERG OHL and OHLK Tool Clamping Cylinders

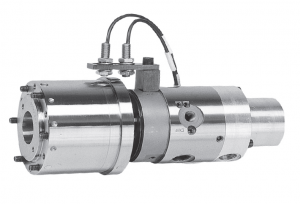

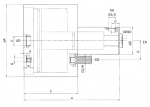

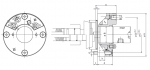

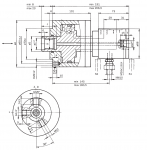

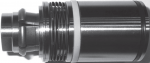

Rotating hydraulic cylinders of the type OHLK..-1 and OHL..-1 are principally designed for actuating SK and HSK clamping sets. All coolant lubrication and compressed air supply variants are possible with a single device to meet the respective requirements. The control system is represented in the circuit diagram T 1345. Unlike spring actuated clamping and chucking systems, OHL(K) ..-1 hydraulic cylinders allow alteration of the clamping forces within wide limits. As the rotating cylinder is permanently connected to the spindle, no axial forces act upon the spindle bearings during tool release and ejection.

![]() PDF Data Sheet: BERG OHL and OHLK Tool Clamping Cylinders (291-OHL-OHLK)

PDF Data Sheet: BERG OHL and OHLK Tool Clamping Cylinders (291-OHL-OHLK)

ApplicationRotating hydraulic cylinders of the type OHLK..-1 and OHL..-1 are principally designed for actuating SK and HSK clamping sets. All coolant lubrication and compressed air supply variants are possible with a single device to meet the respective requirements. The control system is represented in the circuit diagram T 1345. Unlike spring actuated clamping and chucking systems, OHL(K) ..-1 hydraulic cylinders allow alteration of the clamping forces within wide limits. As the rotating cylinder is permanently connected to the spindle, no axial forces act upon the spindle bearings during tool release and ejection.

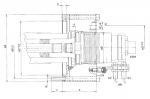

Design FeaturesThe type OHLK ..-1 comprises the function groups cylinder and hydraulic rotary transmission leadthrough with integrated compressed air lead-in, a stroke control device, as well as the coolant rotary lead-in KDE8-1, not included in the cylinder type OHL ..-1.

Both types contain a pilot controlled check valve which maintains the pressure in the clamping direction if the hydraulics fail. In such a case a pressure switch, to be installed on the machine side, triggers the spindle stop. When depressurized, spring elements counteract the weight of the tool with the retaining force FH.

When the piston is in ejection position, compressed air enters connection AL in the cylinder body and escapes again through two holes LA provided at the front.

In addition to the connection AL, an inlet KL is additionally provided for the central compressed air guide. If tools without hole are used, relieve any possibly remaining residual air pressure according to circuit diagram T 1345 before the spindle starts up.

The coolant rotary lead-in KDE8-1 of the cylinder OHLK..-1 is provided for the central supply of coolant lubricant. The glide rings only come into contact with each other when the medium flows in through connection KL. The coolant lubricant escapes through channel KA. Any possibly leaking coolant lubricant can escape through connection LK.

No additional control system is required for a dry run.

The cylinder can be mounted in any required position. When the cylinder is mounted horizontally, ensure that connection LK points vertically downwards.

Ensure that the spindle does not rotate when the cylinder is in release position.

The stroke control device is prepared for accommodating the inductive proximity switches S1 and S2. Optional control of a third position by way of an additional sensor S3 is possible, if required.

Protection hoods SHA ..-1 are available if there is a possibility that foreign bodies or spray oil may enter the open air holes on the cylinder side in the event of connection to AL.

For more information regarding this item (BERG OHL and OHLK Tool Clamping Cylinders) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HDT Tool Clamping Cylinders

HDT pressure intensifiers are primarily designed for tool clamping and chucking systems using stationary hydraulic cylinders of the type HLZ for releasing the tool shanks when no hydraulic unit is available for operating them.

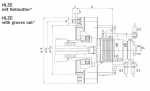

HLZ Tool Clamping Cylinders

HLZ hydraulic cylinders, in conjunction with spring actuated tool clamping and chucking devices, are intended for release and ejection of steep taper tooling and for stationary mounting.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

HLZE Tool Clamping Cylinders

HLZE hydraulic cylinders are designed for release and ejection of the tools in conjunction with spring actuated tool clamping devices and for stationary fitting. The HLZE series is used for applications in which the spindle bearing must not be submitted to the load of the actuation forces during tool changing.

OSKL Tool Clamping Cylinders

OSKL rotating hydraulic cylinders are primarily designed for actuating SSK gripper, but are also suitable for operating other clamping and chucking systems.

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.