240.590

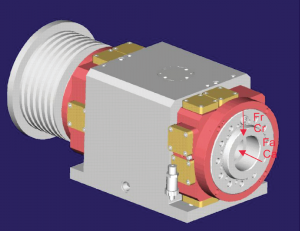

Hydrostatic Lathe Spindles

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller. - No vibration from roller bearings for extremely smooth operation. - Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

Features of Hydrostatic Lathe Spindles • Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller.

• No vibration from roller bearings for extremely smooth operation.

• Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

• Very high axial and radial stiffness, allowing required dimensions to be reached faster

and more precisely. Excellent roundness of grinding diameters.

• High load capacity.

• Speed and stiffness are independent and full load turning from 0 to maximum speed is

possible.

• Wear-free because there is no contact between moving parts when in operation.

• No loss of accuracy, even under full load at maximum speed.

• Less sensitive to chips and other debris because the bearings are cleaned continuously with hydrostatic oil.

• Gap is sealed with a compressor air lock which keeps the oil in the spindle and keeps

machining coolant and chips out.

• The spindle is supplied with a properly sized hydraulic power unit with chiller. The system is designed to protect the internal bearings should electrical power fail.

• The spindle can be driven by belt, direct drive, or as a motor spindle.

• Static and dynamic bearing forces from the cutting force or unbalance of the workpiece can be detected by measuring the pocket pressure.

• The hydrostatic lathe spindle is especially well suited to horizontal or vertical turning

machines or for mill / turning machines.

• The hydrostatic spindle can be adapted to specific machining force and torque requirements

For more information regarding this item (Hydrostatic Lathe Spindles) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Lathe Bridge Alignment Gauge

The Lathe Bridge Alignment Gauge provides an easy-to-use reference surface for an A2 lathe spindle interface.

A2 and D1 Flanged Lathe Spindle Runout Test Bars

Test arbor for mounting to turning-center and measuring run-out. Designed for A2-5, A2-6, D1-8 etc. lathe face mounting. Also available for flat 110 and 140 lathe face.

Extended drawbar clearance versions have additional depth at the taper needed for drawbar clearance on certain lathes.

Lathe Spindle Face Ring

Series 492.026 ring gauges are for lathe spindle face.

Ring only: order plug gauge separately (see series 492.028 or 492.228)

VDI Lathe Turret Alignment Bars

Lathe turret alignment bar for VDI interface. Used for both testing concentricity of the interface as well as center alignment and adjustment on a lathe. Made to DIN 69880 standard.

465.V50.59767 is a special configuration used on certain Mazak machines. Contact us for further information.

Contact us for other sizes or special requirements/configurations.

Application: Hydrostatic Rotary Tables

The world's largest gear and profile grinding machines use hydrostatic bearings.

Lathe Spindle Face Ring With Indicator Mounts

Series 492.126 ring gauges are for lathe spindle face.

Lathe Turret Alignment Bars

Lathe turret test bars provide an easy way to verify turret perpendicularity. Bars are installed in the turret like a standard tool. Test bars have an accuracy of 0.003mm (0.00012 inch) and include a carrying case and certificate.