80.303.00

Centro Setup Indicator - Centro Straight Probe Tip with Ball

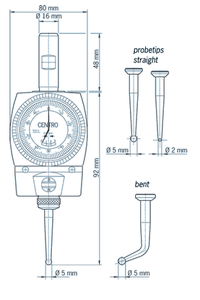

| Product | Accessory |

| Part Type | Machine Setup Indicator |

| Probe Ø | 2 mm |

| Shaft Ø | - |

| Accuracy | .003 mm |

| Max. Rotation | 150 rpm |

| Item | Probe Ø | Shaft Ø | Accuracy | Max. Rotation | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| Centro Centering Indicator w/ Straight Probe Tip | 5 mm | 16 mm | .003 mm | 150 rpm | 80.300.00 | |||

| - | 16 mm | .003 mm | 150 rpm | 80.300.00.FHN | ||||

| Centro Straight Probe Tip with Ball | 5 mm | - | .003 mm | 150 rpm | 80.301.00 | |||

| Centro Bent Probe Tip with Ball | 5 mm | - | .003 mm | 150 rpm | 80.302.00 | |||

| Centro Straight Probe Tip with Ball | 2 mm | - | .003 mm | 150 rpm | 80.303.00 |

For more information regarding this item (Centro Setup Indicator - Centro Straight Probe Tip with Ball) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Centro Setup Indicator

With the CENTRO, bores and shafts can be easily and precisely centered. The CENTRO is clamped into a tool holder and inserted into the spindle of the milling machine. The machine spindle is then positioned near the bore or shaft that is to be measured, and rotates at low speed.

Zero Master Analog Setup Indicator

The Zero Master is the smallest 3D-Sensor worldwide. Usage, function and accuracy are equal to the Universal 3D-Sensor. The size of the Zero Master is adapted to small machines. The clamping shank has a diameter of 10 mm. Thus it can be also used on machines with ISO 30 or with small HSK spindles. The housing is shortened and does not protrude far out of the spindle so that even big work pieces can be measured. The Zero Master can be read with a small analog dial gauge.

3D Universal Setup Indicator

Short and long probes are available. The sensor probes may be changed without any tool. No re-calibration of the unit is needed during a sensor probe change over. Simply bring the needle to Zero, and that is your edge with any probe. The accuracy is such that you are able to inspect your parts right on the machine.

Zero Master Digital Setup Indicator

The dial gauge indicates the distance between spindle axis and workpiece edge. As soon as the gauge shows zero, the spindle axis is exactly on the workpiece edge on the first attempt. This eliminates calculating or problems with positive or negative signs.

3D New Generation Setup Indicator

The 3D-Sensor NG is a further development of our worldwide accepted and proven Universal 3D-Sensor. Its distinguishing features are improved mechanics and a new and compact design.

Spindle Runout Test Arbor Instructions

One of the leading causes of tool breakage, part finish issues, tolerance control, and machine registration issues is excessive spindle runout.

3D Digital Setup Indicator

The digital display has large numbers that measure in increments of 0,001mm. It can be easily read from a long distance (i.e. when mounted on a large machining center). The digital display is splash-proof and dust-proof and can be stored in the tool magazine of the machine.

HSK Dial Indicator Spindle Taper Gauge Manual

Instruction manual for the dial indicator spindle taper gauge (410.310)

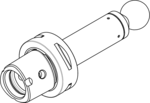

PSC / PSK Taper Standard Ball-End Runout Test Arbors

Precision Spindle Analysis for 5-Axis Machining

Ensure the highest levels of accuracy and performance from your machine tools with the TAC Rockford PSC (Polygonal-Shank Taper) Ball End Test Arbor. Specifically designed for the verification of 5-axis machining centers, this precision instrument is essential for maintaining spindle health and positioning integrity.

Key Features:

PSC Taper Standard: Built to the ISO 26623 Standard for seamless integration and accurate seating in your PSC spindle.

5-Axis Positioning Accuracy: Primarily used for precisely checking the positioning accuracy of 5-axis spindles, especially the Rotary Tool Center Point (RTCP).

Spindle Runout Verification: Functions as a highly accurate runout test arbor to quickly and easily check that your machine spindle is running true.

Versatile Ball End: The precision ball end is ideal for establishing a consistent and repeatable touch-off point from the spindle face, a critical step for machine setup and calibration. It also provides a shorter alternative to standard runout bars when required.

Precision and Reliability: TAC Rockford's commitment to quality ensures a reliable instrument for periodic performance checks, verification after a machine crash, or installation/relocation.

Included Certificate of Accuracy: Each arbor comes with a certificate of accuracy to confirm its adherence to strict quality standards.

HSK PowerClamp Brass Locking Rings

The pressure ball screw must be secured with Loctite 222. Includes pressure ball screw.