492.020

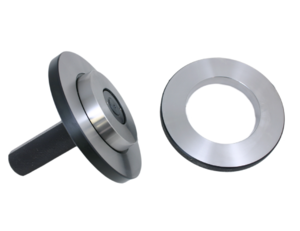

Lathe Spindle Face Ring

Series 492.026 ring gauges are for lathe spindle face.

| Standards | Size | d2 max. | d2 min. | Gauge | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| DIN55026-3, DIN55027-3, A1-3, A2-3, B1-3, B2-3 | 3 | 53.983 | 53.975 | Ring | 492.026.003.000 | |||

| DIN55026-4, DIN55027-4, A1-4, A2-4, B1-4, B2-4 | 4 | 63.521 | 63.513 | Ring | 492.026.004.000 | |||

| DIN55026-5, DIN55027-5, A1-5, A2-5, B1-5, B2-5 | 5 | 82.573 | 82.563 | Ring | 492.026.005.000 | |||

| DIN55026-6, DIN55027-6, A1-6, A2-6, B1-6, B2-6 | 6 | 106.385 | 106.375 | Ring | 492.026.006.000 | |||

| DIN55026-8, DIN55027-8, A1-8, A2-8, B1-8, B2-8 | 8 | 139.731 | 139.719 | Ring | 492.026.008.000 | |||

| DIN55026-11, DIN55027-11, A1-11, A2-11, B1-11, B2-11 | 11 | 196.883 | 196.869 | Ring | 492.026.011.000 |

Series 492.026 ring gauges are for lathe spindle face.

Series 492.028 plug gauges are for chuck back side mounting face.

Taper gauges can be custom-manufactured to customer specifications. Hard chrome-plate and tungsten carbide gauges also available.

Cases are not included. Contact us for high quality gauge crib and travel case options.

For more information regarding this item (Lathe Spindle Face Ring) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Lathe Spindle Face Ring With Indicator Mounts

Series 492.126 ring gauges are for lathe spindle face.

A2 Flanged Lathe Spindle Runout Test Bars

Test arbor for mounting to turning-center and measuring run-out. Designed for A2-5, A2-6, etc. lathe face mounting. Also available for flat 110 and 140 lathe face.

- Maximum runout error 0.003mm [0.00012 in.]

Drive Key Spindle Gauges

When inserted in the spindle, the "go" gauge should be in contact with the plane face. The "no go" gauge should not contact the face. Two measuring gauges in storage case: "go" and "no go" plug gauges.

Centro Setup Indicator

With the CENTRO, bores and shafts can be easily and precisely centered. The CENTRO is clamped into a tool holder and inserted into the spindle of the milling machine. The machine spindle is then positioned near the bore or shaft that is to be measured, and rotates at low speed.

KS Adapter Flanges with Angular Alignment

For fitting onto the machine spindle or on HSK or ISO adapters for holding HSK tools. Can be precisely set in radial run-out by using threaded pins (for alignment) on the machine spindle and on HSK or ISO adapters. Can be precisely set in face run-out using alignment screws (thrust pad and threaded pin) in the adapter flange. Available for HSK-C 32, 40, 50, 63, 80, 100.

Steep Taper Spindle Gauge Manual

Download PDF for instruction manual.

VDI Lathe Turret Alignment Bars

Lathe turret alignment bar for VDI interface. Used for both testing concentricity of the interface as well as center alignment and adjustment on a lathe. Made to DIN 69880 standard.

465.V50.59767 is a special configuration used on certain Mazak machines. Contact us for further information.

Contact us for other sizes or special requirements/configurations.

KS Adapter Flanges with Angular Alignment

Used for fitting onto machine spindle for holding HSK tools. Available for HSK-C 32, 40, 50, 63, 80, 100.