240.510

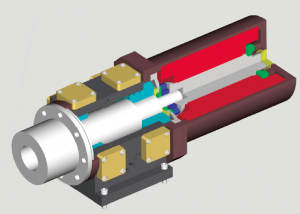

Hydrostatic Grinding Spindles with Integral Motors

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the workpiece. - Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller. - No vibration from roller bearings for extremely smooth operation. - Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

![]() PDF Data Sheet: Hydrostatic Grinding Spindles with Integral Motors (240.510)

PDF Data Sheet: Hydrostatic Grinding Spindles with Integral Motors (240.510)

Features of Hydrostatic Grinding Spindles with Motor • Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece.

• Heat that is generated is moved immediately out of the spindle area with the oil and

cooled in the chiller.

• No vibration from roller bearings for extremely smooth operation.

• Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

• Very high axial and radial stiffness, allowing required dimensions to be reached faster

and more precisely. Excellent roundness of grinding diameters.

• High load capacity.

• Stiffness is independent of speed and load, grinding and dressing can both be performed at maximum speed.

• Wear-free because there is no contact between moving parts when in operation.

• No loss of accuracy, even under full load at maximum speed.

• Not sensitive to grinding grit or other contamination – the bearings are flushed

continuously.

• Gap is sealed with a compressor air lock which keeps the oil in the spindle and keeps

machining coolant and chips out.

• The spindle is supplied with a properly sized hydraulic power unit with chiller. The system is designed to protect the internal bearings should electrical power fail.

For more information regarding this item (Hydrostatic Grinding Spindles with Integral Motors) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

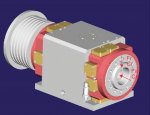

CBN Hydrostatic Grinding Spindle Systems

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

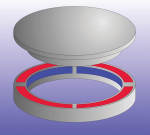

Application: Hydrostatic Rotary Tables

The world's largest gear and profile grinding machines use hydrostatic bearings.

Hydrostatic Lathe Spindles

- Very low friction will heat the spindle only slightly. Nearly all motor power gets to the

workpiece. Heat that is generated is moved immediately out of the spindle area with the oil and cooled in the chiller.

- No vibration from roller bearings for extremely smooth operation.

- Excellent damping of vibration during grinding process, resulting in superior surface finish and workpiece accuracy. In addition, grinding wheels will stay sharp longer.

Hydrostatic Rotary Tables

Application example of a glass grinding machine used at Zeiss.

Application: Hydrostatic Linear Motor Guide

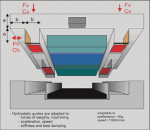

Linear motors are used on high-speed machine tools with high acceleration and slide speeds. For slides with linear motors, HYPROSTATIK has developed hydrostatic guideways that have no wear, excellent damping characteristics, high stiffness and much lower friction when compared with ball or roller rails.

Hydrostatic Universal Bearings

- Frictionless even at minute revolutions

- Transmits minute rotating motion

- No backlash when reversing direction

- Slip-stick effect is eliminated

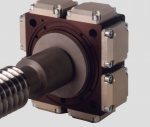

Hydrostatic Linear Motor Guide

The PM Flow Controller makes it possible for machine builders to easily integrate custom hydrostatic systems into both new and existing machines.

Hydrostatic Grinding Spindles

Radial Diameter: 24 mm

Maximum Speed: 35,000 RPM

Maximum Radial Load: 800 N

Radial Stiffness: 70 N/micro-m

Pump and Friction Power: 0.58 kW at 35,000 RPM

Mini Water Cooler

The BKW Mini Water Color can be used for many diverse applications. Some examples include welding machinery, Laser-Plasma installations, electron microscopes, X-ray tubes, hydraulic systems, plastic molding machinery, spindles, motors, cleaning and degreasing installations, as well as numerous other applications.