292-SPH-V

BERG SPH-V Pallet Clamping Heads

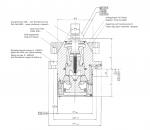

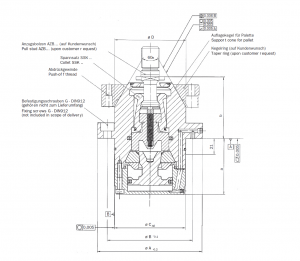

Clamping heads of the series SPH-V are principally used in machining centers for vertical pallet clamping. The series SPH-V is based on the basic principle of the SPH. The additional internal self-locking system retains the clamping force even when hydraulic pressure is not present. It is possible to machine workpieces on a vertical pallet after clamping without a hydraulic connection - without any reduction in safety!

![]() PDF Data Sheet: BERG SPH-V Pallet Clamping Heads (292-SPH-V)

PDF Data Sheet: BERG SPH-V Pallet Clamping Heads (292-SPH-V)

Design FeaturesThe shape and positioning accuracy of the clamping cones guarantee maximum pallet change repeating accuracy. The cone surfaces have a surface hardness greater than 60 HRC and special hardness depth which is resistant to any kind of contamination.

SPH-V clamping heads use a self-locking force intensification mechanism connected to the clamping segments. The retention bolt and tapered ring mounted on the pallet are pulled via the clamping segments onto the clamping head.

An air jet with optimized air guidance is provided to keep the clamping cones clean during pallet changing. These channels can also be used as coolant lubricant channels for rinsing out the clamping heads.

AccessoriesTaper ring, pull stud, clamping force measuring system.

For more information regarding this item (BERG SPH-V Pallet Clamping Heads) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

NAB Pull Studs

Pull studs are the interface between devices, pallets and the clamping systems of the machine tool. For applications with two, four or more clamping heads, solid bolts are used for center position, sword bolts are used to determine the angled position and retaining bolts are exclusively used for vertical positioning. Versions are available for both front and rear installation.

Parallel to the applications of the BERG clamping heads with support cone, screw-in bolts are available as solid bolts and retaining bolts with screw thread. These are used for very high drawing-in forces and maximum stability in a minimum amount of space.

NSM-HV Zero Point Clamping System

NSM-HV series zero point clamping heads are used for workholding pallet clamping as well as other applications on machine tools. With the clamping heads and matching retention bolts, extremely tight tolerance clamping position repeat precision can be achieved.

NSM-PV Zero Point Clamping System

NSM PV zero point clamping heads are used for fixture and pallet clamping on machine tools. With the clamping heads and the associated clamping bolts provide for the highest levels of clamping position repeatability. Due to the mechanical integrated booster and lock, the clamping head is also suitable for pallets, tombstones, pivot tables and vertical applications. The chuck can be configured as double, 4-fold and custom multi-application.

SPH Pallet Clamping Heads

BERG Spanntechnik series SPH clamping heads are primarily used for horizontal pallet clamping. The heads form the basis of a highly rigid, high precision repeatable workholding solution. In addition to clamping heads, non-active units are available for setup and storage stations. Heads are supplied as a matched set with 0.005mm accuracy.

SPM-HV Pallet Clamping Heads

SPM-HV series pallet clamping heads are used for pallet clamping on single or double axis indexing tables. With the clamping heads and matching tapered rings, maximum workpiece position repeatability and precision is possible.

Hydrodock System

Hydrodock units form the basis of a very compact and flexible clamping system. They were originally conceptualized as for head change systems on large machining centers, but also find applications in diverse areas such as injection molding machines.