230.208

Kuma Internal Bed Filters

This type of filter can be used in all treatments where small chips and fine particles are to be filtered out of liquids even if these are of a rather high viscosity. This type of filter has proved its worth and efficiency not only in machining stations, but also in grinding machines, honing machines and wash water conditioning. This filter can be used as an individual system, but also for supplying several machines simultaneously.

This type of filter can be used in all treatments where small chips and fine particles are to be filtered out of liquids even if these are of a rather high viscosity. This type of filter has proved its worth and efficiency not only in machining stations, but also in grinding machines, honing machines and wash water conditioning. This filter can be used as an individual system, but also for supplying several machines simultaneously.

FunctionTwo disk wheels form the thrust bearing for the circulating supporting belt. The non-woven filter is drawn in between these disk wheels by a motor. During this procedure, the non-woven filter forms a circular arc-shaped filtration basin sealed on both sides. The coolant is fed in smoothly through a flat distributor. The incoming liquid flows in the transport direction of the non-woven filter and ensures that the non-woven is kept clean in the feed zone while maintaining a good permeability. The particles to be filtered out deposit in the calmed liquid zone where they form a filter sludge cake taking on to an increasing extent the effect of a filtration auxiliary and so even retaining the smallest particles. After saturation of the non-woven filter, the liquid level in the filter cavity increases. Once the maximum liquid level has been reached, the level switch will set the gear motor into operation. The non-woven filter is renewed automatically, and the section charged with sludge is discharged at the opposite side.

Structure • Solid steel plate housing

• Admission through a distribution box

• Discharge through the bottom side of the filter

• Steel honeycomb band serving as a support for the non-woven filter

• Helical gear motor ensuring the drive (optional)

Advantages • Continuous operation

• Minor space requirements – low maintenance requirements

• Reduced consumption of non-woven filter material

• Longer service life of the cooling lubricant

• Quality of the filtration medium can be adjusted to the production process.

For more information regarding this item (Kuma Internal Bed Filters) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Coolant Supply Measuring Instruments

Quickly and simply check the filtering efficiency of the coolant system. Thanks to replaceable stainless steel filters, the user can adapt the instrument specifically to the filtering of the coolant system. Establishes the present condition of the individual system and displays the actual filter efficiency.

Vacuum Band Filters

Continuous purification of soiled cooling lubricants, as they are produced when operating machine tools. Purification of liquids from industrial washing plants and dust extraction plants and systems. It makes sense to use such a Vacuum Band filter with high throughput rates, because the throughput in a Vacuum Band Filter is 3 to 4 times higher than in a Gravitation Band Filter while the filtration area is identical. The Vacuum Band Filter consumes less filtration material.

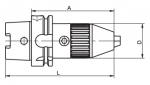

GUHROJET HSK-A Heat Shrink Fit Chucks with Peripheral Cooling

- Optimized cooling for tools without internal coolant ducts

- Good for chip evacuation and increased process reliability

- Balancing quality G6.3 / 15,000 rpm

- For tool shank tolerance h6

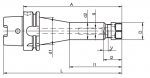

HSK-A Drill Chucks

Available for HSK-A 50, 63, 80, 100

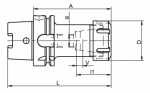

MQL HSK-C 4 Point Manual Clamping Sets

The central and coaxial MQL supply with constant internal diameter prevents coolant from consolidating. For a coolant pressure up to 80 bar.

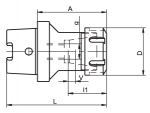

HSK-A Collet Chucks for ER/ESX ER-11/16 Collets with Internal Thread

Available for HSK-A 40, 50, 63, 100

HSK-C Collet Chucks for ER/ESX ER-25/32/40 Collets with Internal Thread

Available for HSK-C 63, 100

HSK-A Collet Chucks for ER/ESX ER-25/32/40 Collets with Internal Thread

Available for HSK-A 40, 50, 63, 80, 100