80.360.00.IN

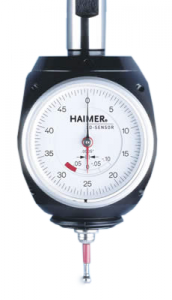

3D Universal Setup Indicator - Sensor Universal Analog, Inch

| Product | Accessory |

| Part Type | Machine Setup Indicator |

| Shank Ø | 3/4" |

| Accuracy | 0.0004" |

| Length | 1" |

| Item | Shank Ø | Accuracy | Length | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| Sensor Universal Analog, Metric | 22 mm | 0.01 mm | 113 mm | 80.360.00 | ||||

| Sensor Universal Analog, Inch | 3/4" | 0.0004" | 1" | 80.360.00.IN | ||||

| Short Probe Tip | 0.2" | 0.0004" | 1" | 80.365.20 | ||||

| Long Probe Tip | 0.4" | 0.0004" | 2.6" | 80.365.30 |

For more information regarding this item (3D Universal Setup Indicator - Sensor Universal Analog, Inch) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Zero Master Analog Setup Indicator

The Zero Master is the smallest 3D-Sensor worldwide. Usage, function and accuracy are equal to the Universal 3D-Sensor. The size of the Zero Master is adapted to small machines. The clamping shank has a diameter of 10 mm. Thus it can be also used on machines with ISO 30 or with small HSK spindles. The housing is shortened and does not protrude far out of the spindle so that even big work pieces can be measured. The Zero Master can be read with a small analog dial gauge.

3D New Generation Setup Indicator

The 3D-Sensor NG is a further development of our worldwide accepted and proven Universal 3D-Sensor. Its distinguishing features are improved mechanics and a new and compact design.

3D Universal Setup Indicator

Short and long probes are available. The sensor probes may be changed without any tool. No re-calibration of the unit is needed during a sensor probe change over. Simply bring the needle to Zero, and that is your edge with any probe. The accuracy is such that you are able to inspect your parts right on the machine.

3D Digital Setup Indicator

The digital display has large numbers that measure in increments of 0,001mm. It can be easily read from a long distance (i.e. when mounted on a large machining center). The digital display is splash-proof and dust-proof and can be stored in the tool magazine of the machine.

Displays

The display is universal and can be used on multiple ForceCheck adapters.

Large Diameter VTL Chuck Force Gauges

Measure clamping force on 12+ inch diameter chucks. Available as wired or wireless sensor unit. Base set is separate which includes wired or wireless read-out display, custom case, and accessories for the sensor.

ForceCheck Hydraulic Tool Holder Force Gauges

Hydraulic tool holders are an excellent ultra-low option with added benefits such as vibration damping and ease of use. One of the major challenges with hydraulic holders is determining if they are still functioning correctly over time. Failure of the hydaulic holding mechanism is often not apparent until cutter slippage occurs, potentially causing damage to both the holder and a scrapped workpiece.

ForceCheck hydraulic tool holder force gauges provide a quick and reliable way to verify a tool holder is still operating correctly. The sensor measures the force at the center of the hydraulic sleeve.

Using the gauge is as easy as inserting the sensor in the hydraulic holder. Once the actuation piston compresses the hydraulic fluid in the expansion sleeve, the resulting force is shown on a handheld digital display. The measured force can be compared to a new or known-good hydraulic tool holder.

Engine and Machinery Mounts

Steel-spring combination for high efficient shock and vibration absorption in order to avoid creep from elastomer springs and readjustment of machines respectively. We provide custom-designed mounts for all kinds of machines and engines (fixation on the side, straight fixation, universal fixation, fixation of the edge).

Centro Setup Indicator

With the CENTRO, bores and shafts can be easily and precisely centered. The CENTRO is clamped into a tool holder and inserted into the spindle of the milling machine. The machine spindle is then positioned near the bore or shaft that is to be measured, and rotates at low speed.

Zero Master Digital Setup Indicator

The dial gauge indicates the distance between spindle axis and workpiece edge. As soon as the gauge shows zero, the spindle axis is exactly on the workpiece edge on the first attempt. This eliminates calculating or problems with positive or negative signs.