682.420.0100

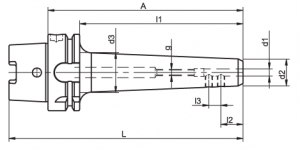

Kelch HSK-A Reduction Sleeves for Straight Shanks with Inclined Clamping Surface (Whistle Notch)

DIN 69 882-5

Available for HSK-A 40, 50, 63, 80, 100

UseFor holding shank tools with inclined clamping surface (2 degrees), DIN 1835 type E and DIN 6535 type HE.

DesignPermissible concentricity deviation of hollow taper shank to location hole d 1 = 0.003 mm (measured at 3 x D cantilever length). Chucks are fine balanced according to ISO 1940-1 G 6.3 at 12,000 rpm.

Standard SpecificationClamping screw and adjusting screw included. From location hole d1 = 25 mm 2 clamping screws are included.

NoteFor an increased machining accuracy the bore tolerance is much reduced compared to DIN 1835.

Bored through adjusting screw for coolant. Other designs and sizes are available on request.

For more information regarding this item (Kelch HSK-A Reduction Sleeves for Straight Shanks with Inclined Clamping Surface (Whistle Notch)) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK-A Reduction Sleeves for Straight Shanks Slim Version

Available for HSK-A 63

HSK-A Reduction Sleeves for Straight Shanks with Lateral Driving Surface (Weldon)

Available for HSK-A 40, 50, 63, 80, 100

HSK-A Reduction Sleeves for Straight Shanks with Lateral Driving Surface, Conical Version

Available for HSK-A 63, 100

HSK-A Side Lock Holders (Whistle Notch)

Available for HSK-A 32, 40, 50, 63, 80, 100

HSK-C Side Lock Holders

Available for 32, 40, 50, 63

HSK-A Reduction Sleeves for Morse Tapers with Tang

Available for HSK-A 50, 63, 80, 100

HSK-A Reduction Sleeves for Morse Tapers with Thread

Available for HSK-A 50, 63, 80, 100

HSK-A Collet Chucks for ER/ESX ER-11/16 Collets with Internal Thread

Available for HSK-A 40, 50, 63, 100

HSK-C Weldon and Whistle-Notch Holders

The hole diameter and circular deviation tolerances have been significantly tightened up compared with DIN 1835 in order to achieve the highest levels of machining precision. Available for HSK-C 32, 40, 50, 63.