291-OSKL

BERG OSKL Tool Clamping Cylinders

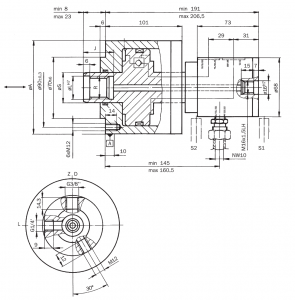

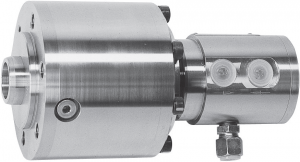

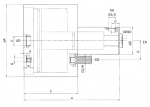

OSKL rotating hydraulic cylinders are primarily designed for actuating SSK gripper, but are also suitable for operating other clamping and chucking systems.

![]() PDF Data Sheet: BERG OSKL Tool Clamping Cylinders (291-OSKL)

PDF Data Sheet: BERG OSKL Tool Clamping Cylinders (291-OSKL)

ApplicationOSKL rotating hydraulic cylinders are primarily designed for actuating SSK gripper, but are also suitable for operating other clamping and chucking systems.

Design FeaturesOSKL hydraulic cylinders comprise the rotating cylinder body and a hydraulic rotary transmission leadthrough which moves axially with the piston. Clamping and release are

per formed hydraulically. In the event of a hydraulic supply failure, a pilot controlled check valve maintains the pressure in the clamping direction and thus the clamping force. The residual clamping pressure in the cylinder can be checked by way of the test connection provided. If the hydraulic supply remains switched off for a prolonged period while the tools are in the spindle, ensure that the weights of the tool and the draw bar are held by a spring element.

In comparison to clamping systems operating with plate

springs, the clamping forces of OSKL hydraulic cylinders are infinitely variable throughout the wide pressure range. No axial forces act upon the spindle bearings during release and ejection of the tools as the rotating cylinder body

is permanently fixed to the spindle.

The central hole permits the supply of compressed air or coolant lubricant; a threaded connection is provided for the Deublin rotary lead-in 1106, which does not, however, allow dry running.

The external edges of the hydraulic rotary transmission leadthrough, in conjunction with inductive proximity switches to be installed on the machine side, are suitable for monitoring the clamping and release position.

Install horizontally or vertically with the hydraulic transmission leadthrough pointing upwards.

For more information regarding this item (BERG OSKL Tool Clamping Cylinders) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

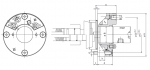

HDT Tool Clamping Cylinders

HDT pressure intensifiers are primarily designed for tool clamping and chucking systems using stationary hydraulic cylinders of the type HLZ for releasing the tool shanks when no hydraulic unit is available for operating them.

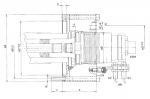

HLZ Tool Clamping Cylinders

HLZ hydraulic cylinders, in conjunction with spring actuated tool clamping and chucking devices, are intended for release and ejection of steep taper tooling and for stationary mounting.

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

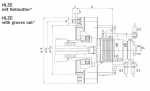

HLZE Tool Clamping Cylinders

HLZE hydraulic cylinders are designed for release and ejection of the tools in conjunction with spring actuated tool clamping devices and for stationary fitting. The HLZE series is used for applications in which the spindle bearing must not be submitted to the load of the actuation forces during tool changing.

Precision Measuring Cylinders

<h3>

<a href="https://tacrockford.com/product/gauges/machine-center-dimensional/master-cylinders/">This product series has been replaced by series 451.CS0. Please follow this link.</a>

</h3>

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

Precision Granite Master Cylinders

TAC Rockford Precision Granite Master Cylinders are the standard for verifying the perpendicularity, straightness, and runout of critical machine axes on high-precision machine tools and CMMs. Manufactured from select, high-density black granite, these cylinders offer unmatched dimensional stability and thermal inertness, making them essential for the most demanding metrology applications.

Standard sizes range from 200mm (7.87in) to 800mm (31.5") in height. Custom diameters, heights, and other special versions available upon request

- contact our engineering team for specialized configurations.