541.004

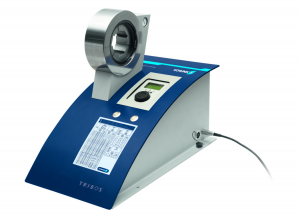

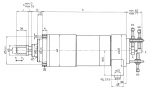

TRIBOS SVP-4 Automatic Clamping Device

Automatic clamping device for user-friendly reliable automatic actuation

Automatic clamping device for user-friendly reliable automatic actuation. Reliable clamping due to pre-set clamping pressure and clamping process only takes seconds.

![]() PDF Data Sheet: TRIBOS SVP-4 Automatic Clamping Device (541.004)

PDF Data Sheet: TRIBOS SVP-4 Automatic Clamping Device (541.004)

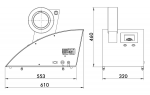

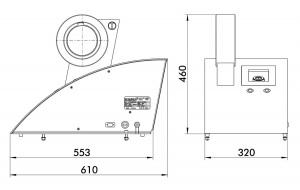

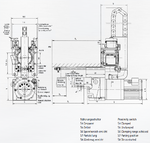

1.) Hydraulic unit for compression.

2.) Mount for length measuring systems for tool pre-setting.

3.) Interface for handheld scanner / identification.

4.) LCD display for handheld scanner / pressure control unit.

5.) Master on/off switch.

Advantages • Reliable clamping due to pre-set clamping pressure.

• Operated at room temperature, therefore no heat, no danger.

• Simple handling via a membrane display.

• Quick clamping process – tool change-over in seconds.

Instructions for clamping/releasing TRIBOS toolholders in SVP-4:

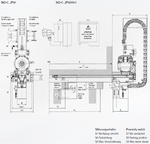

Semi-automatic:

1. Insert the toolholder with reduction insert into the clamping device.

2. Enter the clamping pressure.

3. Confirm or correct the value.

4. Press the START button (if necessary, adjust pressure).

5. The tool may be used or removed.

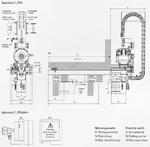

Fully automatic:

1. Insert the toolholder into the clamping device.

2. Read the values via data matrix code on the TRIBOS toolholder using a handheld scanner.

3. Press the START button (if necessary, adjust pressure).

4. The tool may be used or removed.

For more information regarding this item (TRIBOS SVP-4 Automatic Clamping Device) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

TRIBOS Application Example with SRE-R and SVP

An example TRIBOS application with SRE-R inserts and SVP clamping devices.

TRIBOS SVP-2 Manual Pump Clamping Device

Design with manual pump for quick actuation and frequent tool changes.

TRIBOS SVP-2 Assembly and Operating Manual

Design with manual pump for quick actuation and frequent tool changes.

ESK Tool Clamping Cylinders

The electro-mechanical actuator is specifically designed for actuating the SSK gripper. This device generates both the clamping force, adjustable throughout a wide range, as well as the higher release force required for tool ejection. Up to a spindle rotational speed of 4000 rpm, the ESK clamping actuators are advantageous whenever the disadvantages of spring clamping are to be avoided and high clamping forces at relatively low rotational speed, as well as rigid spindle constructions are required. For their function they only require electrical energy which is available virtually everywhere.

Automatic Electromechanical Bellcrank Lever Style Clamping Systems

Electromechanical clamp for die clamping on press slides. The clamp automatically travels between the parking position and the actual die, guided by the T-slot of the slide. The bell-crank lever covers a wider clamping range.

Automatic Hydraulic C-clamping Systems

The C-clamping hydraulic die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is at a maximum 400 bar

Automatic Hydro-mechanical Self-locking C-clamping Systems

The C-clamping hydromechanical self-locking (hydrolock) die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the parking position and the respective die. Clamping and unclamping are performed by a hydromechanical self-locking clamping gear. Hydraulic pressure is at a maximum of 90 bar.

Power Clamp Unshrinking Devices

Unshrinking device for broken tools.

Drawbar Force Gauges

The BERG clamping force measuring system for the tool holders is designed for force measurement when the spindle is stationary! The measuring system consists of a handy sturdy display device in pocket calculator format and the measuring equipment required for the various application. The measured data can be transferred to any WIN 9x/NT PC via a serial standard inter face and represented in y/t. The measuring system includes a practical case for accommodating the display device, the measuring equipment, the charger and the connecting cable.