250.111.515.000

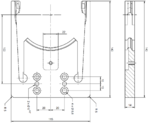

Heavy-Duty Tool Changer Grippers - HSK-E 15 + ATC-E 15

Contact us for optional orientation keys.

For more information regarding this item (Heavy-Duty Tool Changer Grippers - HSK-E 15 + ATC-E 15) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Heavy-Duty Tool Changer Grippers

Heavy duty grippers are designed for demanding applications and where total cost of machine ownership is considered (individual components are replaceable). These grippers have a pivoting finger that allows tool holding force to be adjusted by changing the internal spring. In addition, this unique design minimizes wear on the tool holder.

Contact us for optional orientation keys.

Overview: Heavy-Duty Tool Changer Grippers

TAC offers tool changer grippers for all tool holder types, with common sizes available from stock. We offer customization for specific needs (tool ID chip compatibility, special orientations, and other machine design requirements).

Standard-Duty Tool Changer Grippers

Standard duty grippers are injection molded or machined from specially formulated high-strength fiber reinforced plastics. HSK40 and HSK63 grippers are available from stock for quick delivery.

EHHF and HHHF Handling Systems

The modular handling systems EHHF and HHHF are used as heavy duty grippers in various areas of machine tool and plant engineering.

Heavy-Duty Locking Grippers

The locking gripper offers the same features as the heavy duty gripper, but adds the benefit of a locking mechanism to retain the tool. Because the tool cannot be removed from the gripper, this design is ideal for rapid acceleration or extremely heavy tools. Unlocking can be mechanical, electric, or pneumatic depending on customer requirements.

Standard-Duty Tool Changer Grippers Overview

TAC offers tool changer grippers for all tool holder types, with common sizes available from stock. We offer customization for specific needs (tool ID chip compatibility, special orientations, and other machine design requirements).

Capto Tool Changer Alignment Instruction Manual

The tool changer alignment tool is to verify proper alignment between the automatic tool changer (ATC) and the spindle or clamping unit. See PDF for full instruction manual.

HSK-KM Tool Changer Alignment Gauge Instruction Manual

The tool changer alignment gauge is designed to verify correct alignment of the machine spindle to the Automatic Tool Changer (ATC). See PDF for full instruction manual.

Custom Case Services

TAC Rockford can custom manufacture a gauge case to your exact requirements. Let us know what gauges you want to include in the case, and how you plan to use the case. Customized cases are available in heavy duty plastic, standard duty plastic, and Baltic Birch plywood. Foam is milled for for exact fit and optimal protection of gauges.