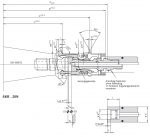

291-HK-HKR

BERG HSK Grippers HK and HKR

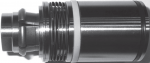

The BERG Spanntechnik HK and HKR series grippers have significant technical advantages, including integrated force intensification, easy-to-machine spindle contour, and a tribolic coating that does not need lubrication. The HKR gripper adds the unique capability of holding a tool with low force before the tool is clamped. This means that the spindle can pull away from the tool changer before tool clamping takes places (a key feature when fast tool change time is needed).

Application

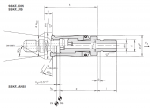

Clamping sets of the type HKR are designed for clamping hollow shank tools according to DIN 69893.

Design Features

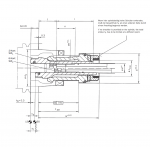

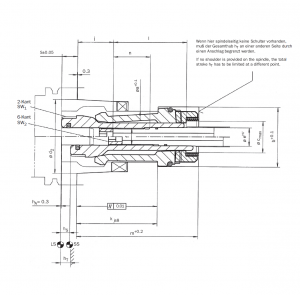

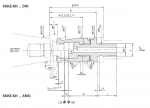

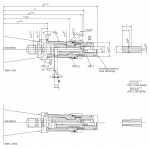

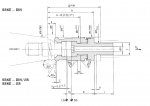

HKR clamping sets have six collets held by an annular spring which allows a rocking movement for inserting and removing the hollow shank tools. During clamping the taper of the centrally positioned draw-bolt increases the actuation force, thereby generating a much higher clamping force at the collets. The special tribolic coating guarantees the highest possible constant clamping force. The clamping set is maintenance free.

A locking bolt permits infinitely variable position and fixation of the clamping set in the Z axis. No special tools are required for assembly and disassembly.

The spindle has an easy to produce interior contour. The HKR gripper has a built-in snap-hold feature allowing a tool to be held securely in the spindle even in an unclamped position.

For more information regarding this item (BERG HSK Grippers HK and HKR) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Pull Studs / Retention Knobs

High-precision retention knobs are available for use with BERG steep taper grippers.

HSK Grippers HSS and HSSL

The BERG Spanntechnik HSS gripper has been replaced by the HK and HKR. Replacement grippers are available for existing machines.

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

Steep Taper Grippers SSKF

With an easy-to-machine spindle contour, BERG Spanntechnik SSKF gripper is designed for cost-sensitive applications.

Steep Taper Grippers SSK

BERG Spanntechnik SSK series grippers are known worldwide for trouble-free operation. Available for CAT/ANSI, DIN, MAS/BT/JIS, and ISO.

SSKS grippers are dimensionally the same as the SSK series, except are designed with additional features for high-speed operation.

Steep Taper Grippers SSKE-KH

SSKE-KH grippers are designed for applications requiring a shorter drawbar stroke.

Steep Taper Grippers SSKV

The BERG Spanntechnik SSKV incorporates a number of new technical innovations, including tool holding force intensification and a special tribolic coating to ensure the highest possible constant clamping force.

Steep Taper Grippers SSKE

Based on the popular SSK design, BERG Spanntechnik SSKE grippers use a common spindle contour for all retention knob standards, greatly simplifying design and production requirements for spindle manufacturers.

SSKES grippers are dimensionally the same as the SSKE series, except are designed with additional features for high-speed operation.

Steep Taper Grippers SKR

The SKR gripper offers the unique capability of holding a tool with low force before the tool is clamped. This means that the spindle can pull away from the tool changer before tool clamping takes place (a key feature when fast tool change time is needed).