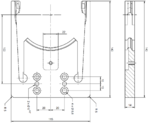

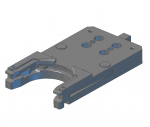

963.14776.000.0

BERG HSK Gripper HSH - BERG Gripper HSH 75 for HSK-A 100

| Product | Gripper |

| Part Type | HSH |

| Taper / Standard | HSK-A |

| Taper Size | 100 |

| Item | Part Number | |||||||

|---|---|---|---|---|---|---|---|---|

| BERG Gripper HSH 48 for HSK-A 63 | 963.14698.000.2 | |||||||

| BERG Gripper HSH 75 for HSK-A 100 | 963.14776.000.0 | |||||||

| BERG Gripper HSH 60 for HSK-A 80 | 963.14777.000.0 | |||||||

| BERG Gripper HSH 38 for HSK-A 50 | 963.15187.000.0 |

For more information regarding this item (BERG HSK Gripper HSH - BERG Gripper HSH 75 for HSK-A 100) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK Gripper HSH

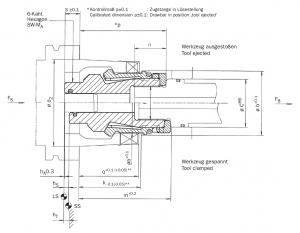

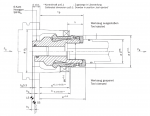

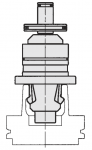

Designed to accommodate significantly higher clamping forces than specified in the HSK standard, the BERG Spanntechnik HSH gripper is ideal for applications requiring an extremely rigid tool holder to spindle interface.

Drawbar Clamping Forces

Drawbar forces in this document are sourced from international standards and gripper manufacturers. This information is for reference only: For specifications applicable to a specific machine, the machine builder should be contacted. Depending on the application, it is typical for a machine builder to design a machine for higher or lower forces.

HSK Hydraulic Self-Locking Clamping Systems

The self-limiting clamping system for HSK tools developed by BERG Spanntechnik is used in conjunction with the proven HSH clamping sets. In this solution the wedge drive itself is rigidly connected to the clamping set via a drawbar.

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

Axial Collet Clamping Grippers for HSK 100 Grinding Wheels

The AZS gripper is specially designed to manually mount heavy grinding wheels to a standard HSK 100 tool interface. The grinding wheel is mounted onto a HSK-style tool holder and is held to the spindle extremely accurately. The gripper allows very high clamping forces in a compact design. For example, the clamping force is 55 kN with a clamping torque of only 30 Nm for HSK 100. If needed, this AXS-100 gripper could be adapted for any HSK standard.

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

Heavy-Duty Locking Grippers

The locking gripper offers the same features as the heavy duty gripper, but adds the benefit of a locking mechanism to retain the tool. Because the tool cannot be removed from the gripper, this design is ideal for rapid acceleration or extremely heavy tools. Unlocking can be mechanical, electric, or pneumatic depending on customer requirements.

Spring Stacks

Spring stacks are used in machining spindles for mechanically generating the actuation force for the clamping means.