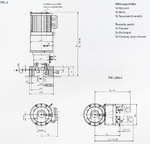

291-HSH

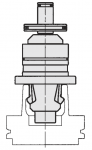

BERG HSK Gripper HSH

Designed to accommodate significantly higher clamping forces than specified in the HSK standard, the BERG Spanntechnik HSH gripper is ideal for applications requiring an extremely rigid tool holder to spindle interface.

Application

For HSC workpiece machining the clamping forces according to DIN 69893 are frequently no longer sufficient. The idea to create an extremely rigid connection between the tool and spindle by placing the clamping element directly against the internal spindle contour, reached its designed limits, due to the cross sections and surfaces available for the force transmission. With their newly developed HSH gripper, BERG-Spanntechnik have met the requirements for clamping forces notably exceeding the values specified in DIN 69893. HSH grippers are intended for the clamping of hollow shank tooling with central cooling lubricant supply.

Design features

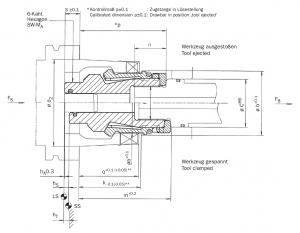

HSH(L) grippers consist of four sturdy clamping claws, held by means of an annular spring, execute a tilting movement when the hollow shank tooling is changed and removed. During clamping, the centrally arranged draw-bolt transfers the actuation force onto the clamping segments, where it acts as a direct clamping force without further force deviation. The generously dimensioned face of the draw-bolt has been provided for tool ejection. The constructive design of the clamping element offers a large clamping reserve. The internal spindle contour is easy to manufacture.

Note:

The connection parts must be designed such, that when in release position, the back stop is reached either in the hydraulic cylinder or by means of spring force in the spindle. When clamped without a tool, the collet is supported in depth 'm' by the spindle shoulder.

For more information regarding this item (BERG HSK Gripper HSH) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Drawbar Clamping Forces

Drawbar forces in this document are sourced from international standards and gripper manufacturers. This information is for reference only: For specifications applicable to a specific machine, the machine builder should be contacted. Depending on the application, it is typical for a machine builder to design a machine for higher or lower forces.

HSK Hydraulic Self-Locking Clamping Systems

The self-limiting clamping system for HSK tools developed by BERG Spanntechnik is used in conjunction with the proven HSH clamping sets. In this solution the wedge drive itself is rigidly connected to the clamping set via a drawbar.

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

Spring Stacks

Spring stacks are used in machining spindles for mechanically generating the actuation force for the clamping means.

Stationary Electromechanical Gripper Style Clamping Systems

Electromechanical gripper style clamp for die clamping on sides. When unclamping the collet opens in order to disengage the draw bolt of the die.

HSK Grippers HSS and HSSL

The BERG Spanntechnik HSS gripper has been replaced by the HK and HKR. Replacement grippers are available for existing machines.

HSK Grippers HK and HKR

The BERG Spanntechnik HK and HKR series grippers have significant technical advantages, including integrated force intensification, easy-to-machine spindle contour, and a tribolic coating that does not need lubrication.

The HKR gripper adds the unique capability of holding a tool with low force before the tool is clamped. This means that the spindle can pull away from the tool changer before tool clamping takes places (a key feature when fast tool change time is needed).