683.4267.012.032

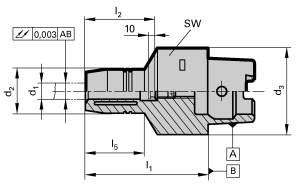

HSK-C 32 Hydraulic Chucks with Increased Clamping Force

| Product | Tool Holder |

| Part Type | Hydraulic Chuck |

| Taper / Standard | HSK-C |

| Taper Size | 32 |

| Ø h6 (d1) | 12 |

| Length (l1) | 76 |

| Taper (d3) | Length (l1) | Ø h6 (d1) | Part Number | |||||

|---|---|---|---|---|---|---|---|---|

| HSK-C 32 | 65 | 6 | 683.4267.006.032 | |||||

| HSK-C 40 | 60 | 6 | 683.4267.006.040 | |||||

| HSK-C 50 | 60 | 6 | 683.4267.006.050 | |||||

| HSK-C 63 | 60 | 6 | 683.4267.006.063 | |||||

| HSK-C 32 | 67 | 8 | 683.4267.008.032 | |||||

| HSK-C 40 | 60 | 8 | 683.4267.008.040 | |||||

| HSK-C 50 | 60 | 8 | 683.4267.008.050 | |||||

| HSK-C 63 | 60 | 8 | 683.4267.008.063 | |||||

| HSK-C 32 | 72.7 | 10 | 683.4267.010.032 | |||||

| HSK-C 40 | 65 | 10 | 683.4267.010.040 | |||||

| HSK-C 50 | 65 | 10 | 683.4267.010.050 | |||||

| HSK-C 63 | 65 | 10 | 683.4267.010.063 | |||||

| HSK-C 32 | 76 | 12 | 683.4267.012.032 | |||||

| HSK-C 40 | 70 | 12 | 683.4267.012.040 | |||||

| HSK-C 50 | 75 | 12 | 683.4267.012.050 | |||||

| HSK-C 63 | 75 | 12 | 683.4267.012.063 | |||||

| HSK-C 50 | 75 | 14 | 683.4267.014.050 | |||||

| HSK-C 63 | 75 | 14 | 683.4267.014.063 | |||||

| HSK-C 50 | 80 | 16 | 683.4267.016.050 | |||||

| HSK-C 63 | 80 | 16 | 683.4267.016.063 | |||||

| HSK-C 50 | 80 | 18 | 683.4267.018.050 | |||||

| HSK-C 63 | 80 | 18 | 683.4267.018.063 | |||||

| HSK-C 50 | 80 | 20 | 683.4267.020.050 | |||||

| HSK-C 63 | 80 | 20 | 683.4267.020.063 | |||||

| HSK-C 63 | 95 | 25 | 683.4267.025.063 | |||||

| HSK-C 63 | 100 | 32 | 683.4267.032.063 |

For more information regarding this item (HSK-C 32 Hydraulic Chucks with Increased Clamping Force) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK-C Hydraulic Chucks with Increased Clamping Force

Available for HSK-C 32, 40, 50, 63

HSK-A Hydraulic Chucks with Increased Clamping Force

Available for HSK-A 32, 40, 50, 63, 80, 100

HSK-C Hydraulic Chucks with Radial Length Setting and Increased Clamping Force

Available for HSK-C 40, 50, 63

Senso 3000 Hydraulic Tool Holder Force Gauge

The SENSO 3000 is a specialized tool for verifying correct operation of hydraulic tool holders. For workholding collet force gauges, please see our ForceCheck collet force gauges.

SENSO 3000 determines the clamping force of the hydraulic chuck via a pressure sensitive plug gauge. The entire length of the plug gauge is clamped in the hydraulic chuck so that when tightening the clamping screw the clamping pressure of the chuck is optimally applied. The clamping force measuring instrument displays the clamping force as an absolute measurement value on the one hand and as a percentage clamping force in relation to a reference value that can be set individually on the other. This way, SENSO 3000 can be adapted to customer specific application conditions and requirements.

The clamping force measuring instrument is supplied with a plug gauge for the respective clamping diameter as well as a carbide proofing bar for calibration purposes and a CR 2430 type battery – all in a sturdy and handy case.

HSK-C Hydraulic Chucks

Available for HSK-C 32, 40, 50, 63

Workpiece Holding Clamping Systems

BERG-Spanntechnik offers an extensive range of power operated chucks and hydraulic cylinders which meet all the requirements of modern CNC lathes as there are effective clamping force, attainable numbers of rotation, and precision, as well as center hole width for bar stock.

HSK-A Hydraulic Expansion Chucks

Available for HSK-A 50, 63, 80, 100

ForceCheck Hydraulic Tool Holder Force Gauges

Hydraulic tool holders are an excellent ultra-low option with added benefits such as vibration damping and ease of use. One of the major challenges with hydraulic holders is determining if they are still functioning correctly over time. Failure of the hydaulic holding mechanism is often not apparent until cutter slippage occurs, potentially causing damage to both the holder and a scrapped workpiece.

ForceCheck hydraulic tool holder force gauges provide a quick and reliable way to verify a tool holder is still operating correctly. The sensor measures the force at the center of the hydraulic sleeve.

Using the gauge is as easy as inserting the sensor in the hydraulic holder. Once the actuation piston compresses the hydraulic fluid in the expansion sleeve, the resulting force is shown on a handheld digital display. The measured force can be compared to a new or known-good hydraulic tool holder.

HSK-C Hydraulic Chucks with Radial Length Setting

Available for HSK-C 40, 50, 63

MQL HSK-A Hydraulic Chucks for Automatic Tool Change

Available for HSK-A 50, 63, 100