455.100

HSK Master Setting Gauges

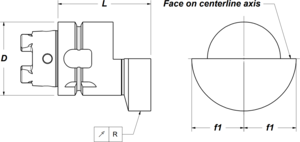

| Taper | L (mm) | D (mm) | f1 (mm) | Part Number | ||||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E/T 25 | Contact us | 455.110.125.000 | ||||||

| HSK-A/C/E/T 32 | Contact us | 455.110.132.000 | ||||||

| HSK-A/C/E/T 40 | 60 | 40 | 27 | 455.110.140.000 | ||||

| HSK-A/C/E/T 50 | 70 | 50 | 35 | 455.110.150.000 | ||||

| HSK-A/C/E/T 63 | 80 | 63 | 45 | 455.110.163.000 | ||||

| HSK-A/C/E/T 80 | 80 | 80 | 50 | 455.110.180.000 | ||||

| HSK-A/C/T 100 | 85 | 100 | 60 | 455.110.190.000 | ||||

| HSK-A/C/T 125 | 90 | 125 | 75 | 455.110.192.000 | ||||

| HSK-F63 63 | 80 | 63 | 45 | 455.110.663.000 | ||||

| HSK-F80 80 | 80 | 80 | 50 | 455.110.680.000 |

To guarantee accurate and repeatable machine accuracy, various other components in the total machining process need to be correctly and accurately positioned. The Center Height Gauge allows the spindle center and spindle orientation to be checked. In addition, the gauge can also be used for tool presetter verification.

Specifications subject to change; contact us when ordering.

For more information regarding this item (HSK Master Setting Gauges) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

HSK Certified Master Taper Gauge

These taper master gauges can be used for zeroing the dial indicators on our HSK Tool Holder Inspection Gauges.

HSK Dial Indicator Spindle Taper Gauge Manual

Instruction manual for the dial indicator spindle taper gauge (410.310)

Tool Holder Taper Check Gauges

<b>This product has been replaced by gauge 430.124.</b> <a href="http://tacrockford.com/product/gauges/tool-holder-taper/steep-taper/tool-holder-taper-inspection-gauges/">Click here to link to this product.</a>

<b>Features</b>

-Maximize tool life and spindle life

-Ensure tool holder performance

-Tool holder can be tested with components assembled, and works with retention knob installed

-Includes (A) and (B) indicators with 0.0001" resolution

-Carbide locating pins for long life

-Made with hardened tool steel body

-Comes with master shank (C)

HSK Tool Holder Taper 30 Degree Clamping Angle Gauges

Using the calibrated master, the distance of the 30 degree clamping slope relative to l 2 is preset using the dial indicator holder. The tool taper to be measured is placed in the centering piece, allowing the variation of the taper to be measured.

Series 968 HSK Tool Holder Taper Gauges

Series 968 gauges offer comprehensive dimensional verification of HSK tool holders.

Dial Indicator Spindle Taper Gauges

To ensure sustained accuracy at HSK interfaces, we recommend comparison measuring of the geometry of HSK tool shanks and spindles at regular intervals. These checks should become more frequent with an increased change rate at the interface. Calibration on request.