560.754

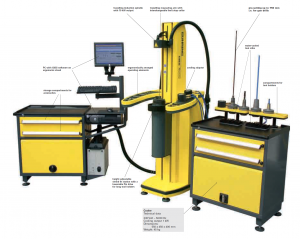

Guhring GISS 4000 Induction Shrink Fit Systems

Using shrink fit chucks as tool holders offers numerous advantages. Simple handling and above all excellent concentricity, extremely low imbalance as well as extreme clamping force, rigidity, longevity, and short shrink fitting for insertion times are convincing attributes.

![]() PDF Data Sheet: Guhring GISS 4000 Induction Shrink Fit Systems (560.754)

PDF Data Sheet: Guhring GISS 4000 Induction Shrink Fit Systems (560.754)

Using shrink fit chucks as tool holders offers numerous advantages. Simple handling and above all excellent concentricity, extremely low imbalance as well as extreme clamping force, rigidity, longevity, and short shrink fitting for insertion times are convincing attributes.

GISS 4000 is especially designed for shrink fitting long tools and the application of special chucks:

• Thanks to its high column, GISS 4000 enables the shrink fitting of tools up to a total length of 750 mm. This makes it possible to clamp and pre-set the length of, for example, gun drills or other extra long tools in shrink fit chucks.

• GISS 4000 is extremely flexible and can be easily adapted to individual customer requirements. It enables the application of special chucks as well as user orientated software.

• The layout of the shrink fit system is extremely ergonomic for easy operation.

• To shrink fit for insertion or removal respectively, tools and shrink fit chucks can simply be inserted or withdrawn because the PIN-drive unit can travel downwards.

• The GISS 4000 system includes an integrated PC with a modern flatscreen monitor on an ergonomic stand.

• The GISS Parameter Management Software administrates all internal and customer tool parameters and is able to communicate with the customer tooling system.

• The tool administration software possesses an integrated label print function.

• GISS 4000 can be further optimized by incorporating a read/write facility for tool data storage.

In addition, GISS 4000 is especially suitable for the automated production with multi-spindle machines and in transfer lines in the automotive and aerospace industry as well as for volume production and offers all the well-known advantages of the GISS 3000 shrink fit system:

• Clamping time: Approximately 5 seconds

• Regulated, energy efficient heating of shrink fit chucks

• No heating of taper

• Incorporated, electronically controlled setting

• Highly accurate length pre-setting of +/- 0.02 mm during the heating phase

• Concentrated cooling with 30 seconds

• Water-cooled, integrated cooling elements

• Optimal process parameters

• Simple operation thanks to intelligent software

• Good mobility as well as workshop suitability

• Excellent cost-efficiency ratio

• Optimal health and safety features

For more information regarding this item (Guhring GISS 4000 Induction Shrink Fit Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

GISS 2500 Induction Shrink Fit Systems

Pre-setting, shrink fitting, and measuring, all possible with one system, the GISS 2500 shrink fit system. In addition to tool pre-setting and induction shrink fitting, it is capable of also measuring the shrink fitting tools thanks to an optical measuring unit and intelligent software.

GISS 3000 Induction Shrink Fit Systems

For the first time GISS 3000 offers the operations shrink fitting, cooling, and high precision length pre-setting in one system. GISS 3000 is especially suitable for the automated production in multi-spindle machines and transfer lines in the automotive industry, in the aerospace industry as well as in volume production.

GISS 5000 Induction Shrink Fit Systems

Like the GISS 2500 system, GISS 5000 pre-setting, shrink fitting and measuring with one facility. In addition, GISS 5000 also offers the possibility of a fully automatic, highly accurate cutting edge form recognition and length pre-setting facility.

Power Clamp Preset Network Heat Shrink Systems

The Power Clamp Preset Network is based on the time-tested Power Clamp Preset. It is equipped with a PC that acts as the interface to your tool management and controls the shrink fit operation as well.

Induction Shrink Fit and Cooling Devices

Compact heat shrink system with fully integrated control, high frequency inductor, and cooling system.

Power Clamp Economic Heat Shrink Systems

High performance shrink fit machine for all tools.

- With standard coil

- Single chuck version

- Without cooling

Power Clamp Economic NG Heat Shrink Systems

High performance shrink fit machine for all tools.

- With intelligent NG coil

- Single chuck version

- Without cooling

Power Clamp Special Edition Heat Shrink Systems

High performance shrink fit machine for all tools.

- With standard coil

- 1-user version

- With integrated contact cooling

Power Clamp Comfort Heat Shrink Systems

High performance shrink fit machine for all tools.

- With standard coil

- Rotary table with 3 stations

- With integrated contact cooling