293-P

BERG Manually-Movable Clamping Systems

The manually actuated die clamping system PSP.AM is designed for clamping dies of various widths on on press slides and tables. The selflocking eccentric cam gear guarantees a simple handling with a maximum of reliability.

![]() PDF Data Sheet: BERG Manually-Movable Clamping Systems (293-P)

PDF Data Sheet: BERG Manually-Movable Clamping Systems (293-P)

BKZ ... P (S) Hydromechanical Clamping System Drawbar Style

The hydraulic die clamping system BKZ.P is designed for clamping tools and dies of different widths on press slides. The variant BKZ.PS is equipped with a nonreturn valve. The variant BKZ.D (D = double acting) is intended for use in confined installation spaces where short clamping and/or release times are required. The variant BKZ.K (K = cup) compensates for nonparallel tool clamping surfaces. The die clamps can be manually moved in the T-groove of the press slide between the park position and the respective tool. The clamping pressure can be 240 or 400 bar.

BKZ C ... PHydraulic C-Clamping System

The hydraulic die clamping system BKZ C.P is designed for clamping tools and dies of different widths on press slides. The variant BKZ C.PS is equipped with a nonreturn valve. The die clamps can be manually moved in the T-groove of the press slide between the park position and the respective tool The clamping pressure is max. 400 bar.

Hydrolock ... PHydromechanical Clamping System Drawbar Style selflocking

The hydromechanical selflocking die clamping system Hydrolock ...P is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is in maximum 90 bar.

Hydrolock C ... PHydromechanical C-Clamping System selflocking

The hydromechanical selflocking die clamping system Hydrolock C...P is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is in maximum 90 bar.

PSP ... AMMechanical Clamping System

The manually actuated die clamping system PSP.AM is designed for clamping dies of various widths on on press slides and tables. The selflocking eccentric cam gear guarantees a simple handling with a maximum of reliability.

PSP-C ... AMMechanical Clamping System

The manually actuated die clamping system PSPC. AM is designed for clamping dies of various widths on press slides and tables. The selflocking eccentric cam gear guarantees a simple handling with a maximum of reliability.

For more information regarding this item (BERG Manually-Movable Clamping Systems) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Manual Hydraulic C-clamping Systems

The hydraulic C-clamp die clamping systems are designed for clamping tools and dies of different widths on press slides. The C-clamp is equipped with a non-return valve. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.

Manual Hydro-mechanical Self-locking C-clamping Systems

The hydromechanical self-locking (hydrolock) C-clamping die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 90 bar.

Manual Mechanical Self-locking Drawbar Style Clamping Systems

The manually actuated drawbar style die clamping system is designed for clamping dies of various widths on press slides and tables. The self-locking eccentric cam gear guarantees a simple handling with a maximum of safety.

Manual Hydro-mechanical Self-locking Drawbar Style Clamping Systems

The hydromechanical self-locking (hydrolock) drawbar style die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator can be moved manually in the T-slot of the press slide between the parking position and the respective die. Hydraulic pressure is at a maximum 90 bar.

Manual Drawbar Style Hydraulic Clamping Systems

The drawbar style hydraulic die clamping systems are designed for clamping tools and dies of different widths on press slides. The BKZ-PS variant is equipped with a non-return valve. The BKZ-D (D = Double-acting) variant is intended for use in confined installation spaces where short clamping and/or release times are required. The BKZ-K (K = Cup) variant compensates for nonparallel tool clamping surfaces. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.

Manually Operated Eccentric Cam Style Transfer Rail Couplings

The mechanical self-locking gripper rail coupling is designed for manual coupling of gripper rails on transfer presses. A vertical life-out stroke is required for changing the tool. The coupling consists of a hard anodized aluminum housing, an axially movable tensioning rod and a self-locking eccentric cam gearing. This configuration allows high clamping forces and features a high dynamic rigidity with minimum mass.

Capto Clamping Systems

BERG Spanntechnik is a leading supplier of Capto grippers and clamping systems.

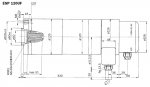

ESP UF Tool Clamping Cylinders

ESP UF electro-mechanical actuators are intended for the power actuated clamping and release of steep taper tooling on milling and boring machines on which the tool change is performed manually. They are firmly connected by way of appropriate connection pieces to the workspindle which has a maximum rotational speed of 4000 rpm. The electrical control can be per formed both manually and automatically.

Overview: Clamping Systems with AS-Interface

The BERG AS-Interface clamping and chucking systems are intended for clamping various tools/dies on press slides and black holders, and for sliding table clamping and gripper rail couplings on multiple die presses. They are used on new machines and for retrofitting automatic clamping systems in existing press lines.