685.AZS.063.A00

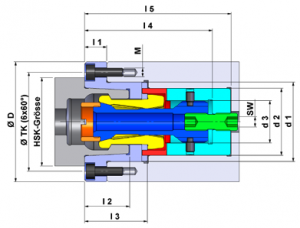

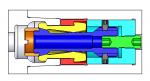

HSK-A/C/E63+B/D/F80 Axial-Clamp Manual Gripper, Version A (Flange Installation)

| HSK-A | HSK-B | Key Size | Torque | Force | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| HSK-A/C/E 32 | HSK-B/D/F 40 | 4 | 3 Nm | 9 kN | 685.AZS.032.A00 | |||

| HSK-A/C/E 40 | HSK-B/D/F 50 | 4 | 6 Nm | 20 kN | 685.AZS.040.A00 | |||

| HSK-A/C/E 50 | HSK-B/D/F 63 | 5 | 10 Nm | 30 kN | 685.AZS.050.A00 | |||

| HSK-A/C/E 63 | HSK-B/D/F 80 | 6 | 12.5 Nm | 40 kN | 685.AZS.063.A00 | |||

| HSK-A/C/E 80 | HSK-B/D/F 100 | 8 | 18 Nm | 60 kN | 685.AZS.080.A00 | |||

| HSK-A/C/E 100 | HSK-B/D/F 125 | 8 | 25 Nm | 80 kN | 685.AZS.100.A00 |

For more information regarding this item (HSK-A/C/E63+B/D/F80 Axial-Clamp Manual Gripper, Version A (Flange Installation)) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Steep Taper Tool Changer Alignment Gauge Instruction Manual

The tool changer alignment gauge is designed to verify correct alignment of the machine spindle to the tool changer. See PDF for full instruction manual.

HSK Tool Changer Alignment Gauges

Available for HSK-A 25, 32, 40, 50, 63, 80, 100, 125, and 160. Includes padded storage case.

Hollow Taper Shank Type D

For use in all areas which require even better support with manual tool changing via a large contact face. Hollow Taper Shanks for Manual Tool Changing acc. to ISO 12164/DIN 69 893 Part 1 and 2 without Gripper Groove.

Mounting Nuts for HSK-A/C Interface Adaption

Can be mounted in front of the spindle shaft after the installation of the collet. Has the advantage of being adaptable to HSK-E or HSK-F tool interfaces in an HSK-A spindle. Just use the drive key to expand and then clamp the desired tool. The ENS slot nuts can also be used in manual clamping units for more flexibility. Available for HSK 32, 40, 50, 63, 80, and 100.

HSK Axial-Clamping Manual Clamping Grippers

The Axial pliers Spanner is a manual HSK-tensioners with axially in the center lying indirect drive, which is accessible both from the front and from behind. It is particularly suitable for clamping of HSK, especially grinding wheel shots, with the AZS can be integrated into the hub of a wheel on the one hand, (HSK arranged vice versa

- the spindle is the father) on the other hand, as usual, can be incorporated into the spindle using flange.

Transfer Rail Couplings

The mechanical self-locking Berg gripper rail coupling GSM is designed for manual coupling of gripper rails on transfer presses. A vertical lift-out stroke is required for changing the tool.

Tool Holder Flange Grippers

Designed for applications where the tool holder flange v-groove needs to be accessible for pickup with a changer arm or other mechanism.

HSK-C 4 Point Manual Clamping Sets for Conventional Cooling

- For a coolant pressure up to 80 bar

- Includes installation and operating instructions