280.001

Oswald TF Torque Motors and Ring Generators

For large torque at low speeds

Direct electric drive, large maximum torque, low rated speed, large hollow shaft, extremely low noise, no rotor losses. Contact us to adapt the electrical and mechanical design to your specific requirements.

![]() PDF Data Sheet: Oswald TF Torque Motors and Ring Generators (280.001)

PDF Data Sheet: Oswald TF Torque Motors and Ring Generators (280.001)

Features • Direct electric drive

• Large maximum torque

• Low rated speed

• Large hollow shaft

• Extremely low noise

• No rotor losses

• With NdFeB magnets

• Without reduction gear, no play at direction reversal

• Optional integrated planetary gear

• Optional integrated axial thrust bearing

Features of Oswald Motors • Compact, robust, high force density

• Maintenance-free or low maintenance

• Low inertia, dynamical

• Long life

• Made in Germany

Technical Specifications • Torque: 100-120,000 Nm

• Power: 5-2000 kW

• Speed: up to 3000 rpm

• Cooling: fluid

• Protection class: IP54

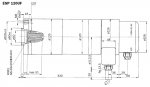

Design • Torque motor: permanent magnet motor, annular geometry with hollow shaft and rare-earth magnets

• Direct drive, high torque at low speed (no need for gearboxes)

• Features: compact, robust, low-maintenance, low cost, motor with excellent control properties, technically comparable with synchronous servomotors

• Bearings are part of motor or part of the customer's machine, axial self-aligning rolelr bearings are optional

Feedback Systems / Brakes / GearsDepending on the frequency inverter and customer demands the rotor position and/or the motor speed have to be determined with suitable feedback systems. Following mounting solutions are available: Hollow shaft encoder, excentrical mounting with belt, encoder mounting on machine parts on site and mounting central on NDE. Also possible is also the mounting of brakes and gears.

Cooling Systems • Standard: liquid cooled motor (copper coolant circuit)

• Anti-corrosion protection is not required, filtering of particles larger than 100micro-m

• Condensation of water should be avoided

• Inlet temperature of the coolant: 25°C nominal. (power level must be reduced at higher temperatures)

• Flow rate of cooling water, water pressure and the pipe fittings according to the table or the nameplate

For more information regarding this item (Oswald TF Torque Motors and Ring Generators) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

MF Synchronous Motors

Liquid-cooled OSWALD synchronous motors and generators series M are particularly suitable when heavy demands are placed on a drive system. The motors are designed for wide speed range and high dynamic operation. OSWALD 6-pole MF motors in power ranges from 1kW to 175kW are characterized by highest power density with small space requirements. High maximum speed, extremely low noise, no rotor losses, comes with NdFeB magnets. Contact us to adapt the electrical and mechanical design to your specific requirements.

FQD Asynchronous Motors with Water Cooling

Liquid-cooled OSWALD asynchronous motors and generators series FQD are particularly suitable when heavy demands are placed on a drive system. The motors are designed for wide speed range and high dynamic operation. OSWALD 4-pole FQD motors in power ranges from 1kW to 700kW are characterized by a high power density with small space requirements. High maximum speed, wide range of field weakening, and extremely low noise. Contact us to adapt the electrical and mechanical design to your specific requirements.

QD Asynchronous Motors with External Cooling

OSWALD asynchronous servomotors series QD are particularly suitable when heavy demands are required with respect to high speed range, dynamics, running smoothness and operational reliability. OSWALD 4-pole QD motors in the power range from 1 kW to 150 kW have quadratic frames and are characterized by a high power density with a small space requirement.

QDI Asynchronous Motors for Test Stands

High maximum speed, wide range of field weakening, very low vibration levels, and standard configuration with hybrid bearings. Contact us to adapt the electrical and mechanical design to your specific requirements.

LIFS Flat Linear Motors

Direct electric drive, high speed, without reduction gear, no play at direction reversal, no rotor losses, and with NdFeB magnets. Contact us to adapt the electrical and mechanical design to your specific requirements.

LINS Cylindrical Linear Motors

Direct electric drive, high acceleration, extremely low noise, without reduction gear, no play at direction reversal, free of lateral forces, no rotor losses, and with NdFeB magnets. Contact us to adapt the electrical and mechanical design to your specific requirements.

Torque Wrenches

- With ratchet - Torque range: 1...200 Nm; with automatic short distance release; can be heard, seen and felt when the set value is reached. Release accuracy ± 4% of the scale value.

Lathe Spindle Face Ring With Indicator Mounts

Series 492.126 ring gauges are for lathe spindle face.

ESP UF Tool Clamping Cylinders

ESP UF electro-mechanical actuators are intended for the power actuated clamping and release of steep taper tooling on milling and boring machines on which the tool change is performed manually. They are firmly connected by way of appropriate connection pieces to the workspindle which has a maximum rotational speed of 4000 rpm. The electrical control can be per formed both manually and automatically.