451.2G3.400.250.050

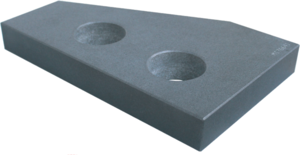

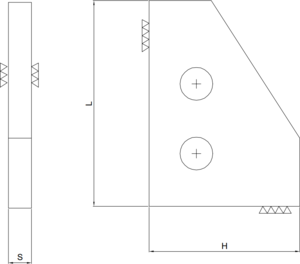

Granite Squares - 400 x 250

| Granite Square | L (mm) | H (mm) | S (mm) | Class | Part Number | |||

|---|---|---|---|---|---|---|---|---|

| 1000 x 630 | 1000 | 630 | 100 | 000 | 451.2G3.1000.630.100 | |||

| 1200 x 800 | 1200 | 800 | 140 | 000 | 451.2G3.1200.800.140 | |||

| 1500 x 1000 | 1500 | 1000 | 160 | 000 | 451.2G3.1500.1000.160 | |||

| 200 x 150 | 200 | 150 | 30 | 000 | 451.2G3.200.150.030 | |||

| 300 x 200 | 300 | 200 | 40 | 000 | 451.2G3.300.200.040 | |||

| 400 x 250 | 400 | 250 | 50 | 000 | 451.2G3.400.250.050 | |||

| 500 x 300 | 500 | 300 | 50 | 000 | 451.2G3.500.300.050 | |||

| 500 x 315 | 500 | 315 | 60 | 000 | 451.2G3.500.315.060 | |||

| 630 x 400 | 630 | 400 | 60 | 000 | 451.2G3.630.400.060 | |||

| 800 x 500 | 800 | 500 | 80 | 000 | 451.2G3.800.500.080 |

For more information regarding this item (Granite Squares - 400 x 250) or other items, fill out the form below

or contact our office directly:

Telephone: 815-962-5600

Fax: 815-962-4600

Location: 304 North Main St, Suite 104, Rockford, IL 61101-1101 USA

Email: infο@ΤΑCRοckfοrd.cοm

Related

Master Granite Setup Squares (90 degrees)

Granite block with two diamond-lapped measuring faces. Made in Germany to DIN 875 / 876 standard.

Special Automotive Springs

Roehrs automotive exhaust system springs are designed for use between the engine and exhaust system. They utilize a fully elastic suspension to minimize bending stress, and are designed for absorption of axial forces and torsion at temperatures up to 400 °C. The springs minimize noise and help to extend the lifetime of the exhaust system since they are constructed of corrosion resistant materials.

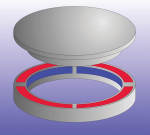

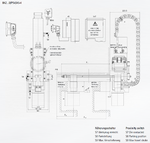

Hydrostatic Rotary Tables

Application example of a glass grinding machine used at Zeiss.

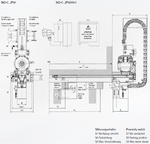

Automatic Hydraulic C-clamping Systems

The C-clamping hydraulic die clamping system is designed for clamping dies of various widths on press slides. The clamping actuator moves automatically in the T-slot of the press slide between the park position and the respective die. Hydraulic pressure is at a maximum 400 bar

Manual Hydraulic C-clamping Systems

The hydraulic C-clamp die clamping systems are designed for clamping tools and dies of different widths on press slides. The C-clamp is equipped with a non-return valve. The die clamps can be manually moved in the T-slot of the press slide between the parking position and the respective tool. Hydraulic pressure is at a maximum 400 bar.

Automatic Hydraulic Drawbar Style Clamping Systems

The hydraulic die clamping system with drawbar style clamping is designed for clamping dies of different widths on press slides. The clamping actuator moves automatically into the T-slot of the press slide between the parking position and the respective die. The clamping element can clamp different clamping rim heights due to the long clamping stroke of the double acting cylinder. Hydraulic pressure is at a maximum 400 bar.